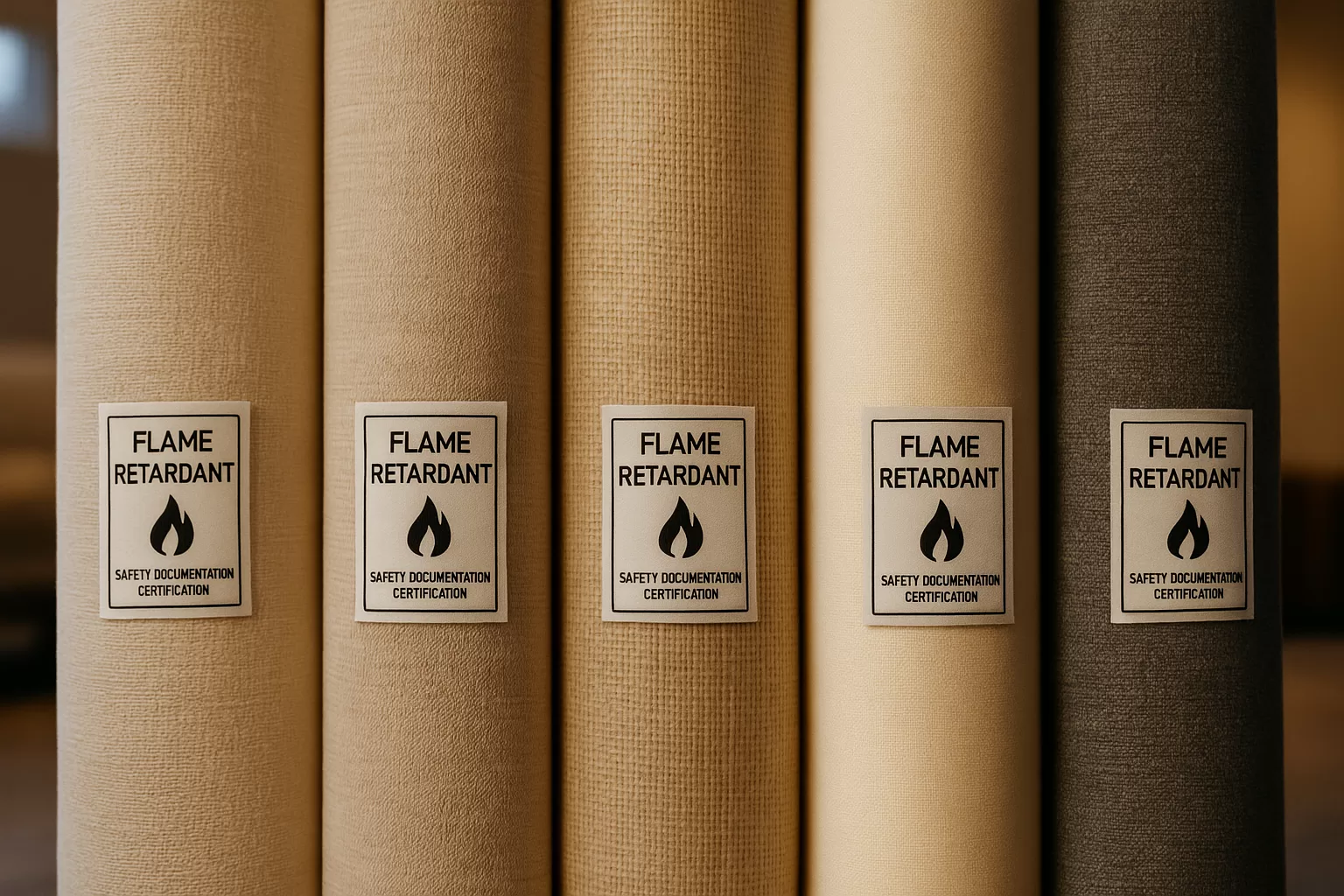

When designing or sourcing fabrics for commercial interiors, transportation, or hospitality environments, safety isn’t optional—it’s essential. In these high-risk or high-occupancy spaces, fire safety regulations often determine what materials can be used, especially in upholstery, drapery, and wallcoverings. That’s where flame retardant fabrics come into play.

But there’s often confusion about what flame retardant fabrics are, how they work, and why they’re needed. Are all flame-resistant fabrics chemically treated? What’s the difference between FR and IFR? And how can you ensure compliance without compromising design?

This guide breaks it all down—so you can make smart, informed choices that protect both your designs and the people interacting with them.

What Are Flame Retardant Fabrics?

Flame retardant (FR) fabrics are textiles that are engineered to resist ignition and slow the spread of fire. These fabrics can either be treated with flame-retardant chemicals after manufacturing or made with inherently fire-resistant fibers from the start.

Their primary purpose is to delay combustion, minimize flame spread, and provide critical seconds of protection in the event of a fire. While they don’t make a material completely fireproof, they play a crucial role in slowing down fire-related hazards—potentially saving lives and reducing property damage.

There are two main types:

-

FR (Flame Retardant): Fabrics that have been chemically treated to achieve flame resistance.

-

IFR (Inherently Flame Retardant): Fabrics made from fibers that are flame resistant by nature, such as aramids or modacrylics.

Why Flame Retardancy Matters—Now More Than Ever

In the past, flame retardant treatments were mostly required in large-scale public buildings. But as fire risk awareness grows and regulations tighten, more industries are implementing FR standards at the manufacturing level.

You’ll now find flame retardant fabric requirements in:

-

Commercial furniture and seating

-

Hotel and hospitality interiors

-

Healthcare facilities

-

Theaters and auditoriums

-

Public transportation seating

-

Schools and universities

-

Government and military contracts

Flame retardant compliance isn’t just about ticking a box—it’s about meeting legal codes, passing fire inspections, and most importantly, creating safe environments where people live, work, and gather.

Common Flame Retardant Standards

Fire regulations vary by state, industry, and application, but here are some of the most widely recognized flame retardant standards in North America:

| Standard | Applies To | Purpose |

|---|---|---|

| NFPA 701 | Drapery, curtains, window treatments | Ensures fabric will not propagate fire when hanging vertically |

| CAL 117 (TB117-2013) | Upholstered furniture (California standard) | Focuses on smolder resistance, often required nationwide |

| ASTM E84 (Steiner Tunnel Test) | Wallcoverings, ceiling treatments | Rates materials on flame spread and smoke development |

| FMVSS 302 | Automotive interiors | Evaluates burn rate of materials inside vehicles |

| IMO FTP Code | Marine vessels | Fire protection for international maritime vessels |

| CAN/ULC-S109 | Canada’s flame testing standard | Similar to NFPA 701 with stricter performance ratings |

Before choosing a fabric, always verify which standards apply to your project based on geography and usage.

Flame Retardant vs. Fire Resistant: What’s the Difference?

These terms are often used interchangeably, but they’re not the same.

-

Flame Retardant (FR): A finish or treatment is applied to a non-resistant fabric to make it meet flame standards.

-

Inherently Flame Resistant (IFR): The fabric’s raw materials (fibers) are naturally resistant to flame—no treatment needed.

-

Fire Resistant: A general term that includes both treated and inherent fabrics and focuses on performance in resisting fire or heat.

Understanding these distinctions is essential when selecting the right material for compliance and performance.

How Are Flame Retardant Fabrics Made?

There are two main production paths:

1. Treated Flame Retardant Fabrics

These start with regular textiles (cotton, polyester blends, etc.) that are chemically treated to enhance their fire resistance. These treatments bond with the fabric fibers to reduce flammability.

Common treatment types include:

-

Durable FR (DFR): Survives multiple cleanings, but not permanent

-

Non-durable FR: Used for temporary applications (e.g., trade shows)

-

Semi-durable FR: Maintains performance for a limited number of launderings

2. Inherently Flame Retardant Fabrics (IFR)

Made from specialized synthetic fibers like:

-

Aramid (e.g., Nomex®, Kevlar®)

-

Modacrylic

-

PBI

-

Polyester with built-in FR properties

These fabrics maintain flame resistance throughout their life cycle and do not lose performance through washing or wear.

Pros and Cons of Treated vs. Inherent FR Fabrics

| Feature | Treated FR | Inherent FR (IFR) |

|---|---|---|

| Cost | Lower upfront | Higher upfront |

| Durability | May degrade over time | Permanent performance |

| Laundering | May reduce FR over time | Maintains FR indefinitely |

| Versatility | Can be applied to more fabric types | Limited to specific fibers |

| Environmental Concerns | Some chemical concerns | Often more eco-friendly depending on fiber |

Treated FR fabrics offer versatility and affordability, while IFR materials deliver longevity and consistent protection.

Environmental and Health Considerations

In recent years, the chemical makeup of FR treatments has come under greater scrutiny—especially with regard to halogenated compounds and PFAS (per- and polyfluoroalkyl substances). These chemicals, while effective at flame resistance, have raised health and environmental concerns.

At SBI Finishing, we’re proud to offer PFAS-free flame retardant treatment options that align with modern sustainability demands. We believe safety shouldn’t come at the cost of human or environmental health—and we continue to innovate safer, compliant alternatives.

When Should You Specify Flame Retardant Fabric?

You should always specify FR fabrics if your project involves any of the following:

-

Public buildings (hotels, theaters, schools, healthcare)

-

Code-compliant wallcoverings or upholstered panels

-

Transportation interiors (planes, trains, buses)

-

Conference centers or rental event drapes

-

Any space where regulations explicitly require flame resistance

Additionally, many insurance policies require FR compliance for liability coverage in certain industries.

How SBI Finishing Helps You Stay Compliant

We provide custom flame retardant treatments for fabrics used in commercial, hospitality, and industrial environments. Whether you’re starting with a raw textile or selecting from existing samples, our team works with you to ensure:

-

Code compliance (NFPA 701, CAL 117, ASTM E84, etc.)

-

Fabric compatibility and performance testing

-

PFAS-free or low-toxicity options when possible

-

Traceable documentation for fire inspectors and regulatory bodies

-

Quick turnaround and reliable batch consistency

You’ll get the fire safety protection you need—without compromising design, texture, or fabric character.

Final Thoughts: Flame Retardant Fabrics Are a Design Asset, Not a Compromise

Too often, safety and aesthetics are seen as opposing forces in the design world. But with modern flame retardant fabrics and expert finishing services, you no longer have to choose between compliance and creativity.

Understanding your options—and working with the right finishing partner—means your textiles will look just as good as they perform. Flame retardant doesn’t mean boring. It means smart, safe, and ready for the real world.

Let’s Fireproof Your Next Project—Without Burning Through Your Vision

Have questions about which fabrics qualify or need treatment? Want to future-proof your textile line to meet growing safety requirements?

Place your order with us at orders.sbifinishing.com/order or call us at 903-675-1440 to learn more